Understanding X-Ray Saturation Point: A Quick Guide

X-ray saturation point is a critical concept in radiology and material science, referring to the maximum density at which an X-ray can effectively penetrate a material. Understanding this concept is essential for professionals in medical imaging, engineering, and quality control. Whether you’re a radiologist, technician, or researcher, knowing how X-ray saturation point works can optimize imaging accuracy and material analysis. This guide breaks down the concept, its applications, and practical tips to enhance your understanding. (X-ray saturation point, radiography principles, material density analysis)

What is X-Ray Saturation Point?

X-ray saturation point is the threshold at which increasing the density of a material prevents further penetration of X-rays. Beyond this point, additional material does not significantly affect the image or analysis. This phenomenon is crucial in determining the optimal conditions for X-ray imaging and material testing.

📌 Note: X-ray saturation point varies depending on the material’s composition and the energy level of the X-ray source.

Why is X-Ray Saturation Point Important?

Understanding X-ray saturation point ensures accurate imaging and reliable material analysis. It helps in:

- Medical Imaging: Avoiding overexposure and ensuring clear diagnostics.

- Industrial Testing: Detecting defects in dense materials without unnecessary radiation.

- Research: Calibrating equipment for precise measurements.

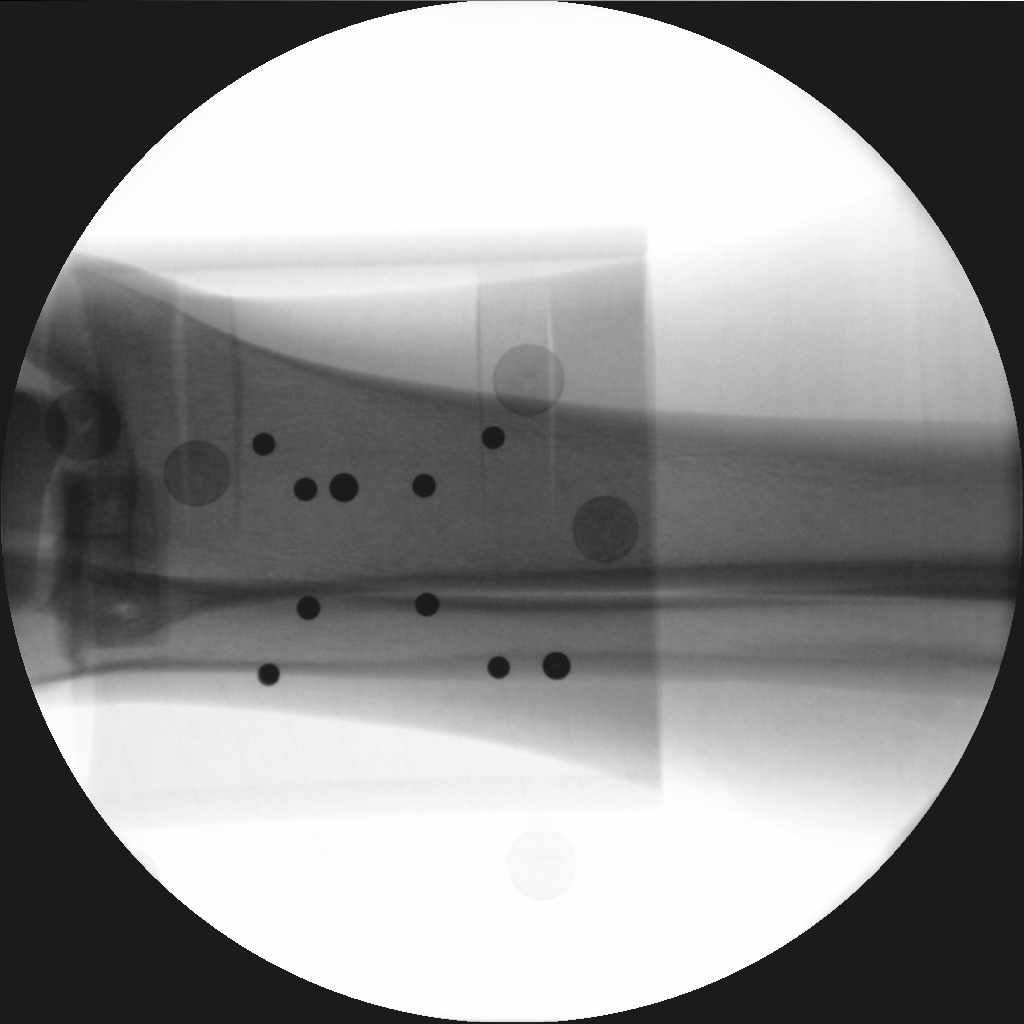

How to Determine X-Ray Saturation Point

Determining the X-ray saturation point involves the following steps:

1. Select the Material: Identify the material being tested.

2. Adjust X-Ray Energy: Use an appropriate energy level for the material’s density.

3. Measure Penetration: Gradually increase material thickness and observe X-ray penetration.

4. Identify Threshold: Note the point where further density does not affect penetration.

| Material | Typical Saturation Point |

|---|---|

| Aluminum | 5-10 mm |

| Steel | 10-20 mm |

| Lead | 1-2 mm |

📌 Note: Always refer to material-specific data for accurate saturation points.

Practical Applications of X-Ray Saturation Point

Medical Field

In radiography, understanding saturation point ensures patients receive the correct radiation dose for clear imaging without overexposure.

Industrial Sector

Manufacturers use this concept to inspect welds, detect cracks, and ensure material integrity in dense components.

Research and Development

Researchers rely on saturation point data to develop new materials and improve imaging technologies.

Checklist for Working with X-Ray Saturation Point

- Verify Material Composition: Ensure you know the material’s density and properties.

- Calibrate Equipment: Use properly calibrated X-ray machines for accurate readings.

- Record Data: Document saturation points for future reference.

- Safety First: Follow radiation safety protocols to protect operators and patients.

To summarize, X-ray saturation point is a fundamental concept that impacts the accuracy and efficiency of X-ray imaging and material analysis. By understanding and applying this knowledge, professionals can optimize their work, ensuring safer and more effective outcomes. Whether in medicine, industry, or research, mastering this concept is key to success. (X-ray imaging techniques, material testing methods, radiation safety)

What factors influence X-ray saturation point?

+Material density, X-ray energy level, and thickness are the primary factors influencing saturation point.

Can X-ray saturation point be exceeded?

+Yes, but exceeding it provides no additional imaging or analytical benefits and may increase radiation exposure.

How does saturation point affect medical imaging?

+It ensures proper exposure, preventing underexposed or overexposed images, which are crucial for accurate diagnostics.